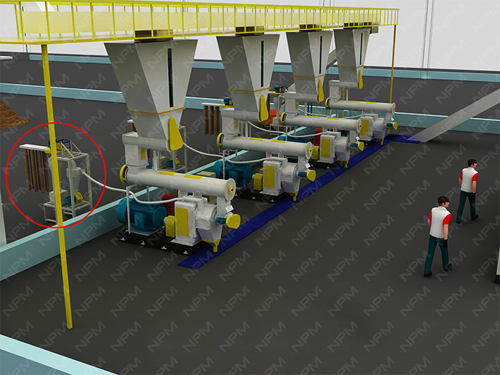

ABC Machinery Patented Cooling System for Ring Die Pellet Mill

ABC Machinery is proud to introduce the cooling system for ring die pellet mill, an innovative design invented in 2008. We’ve successfully obtained the patent for this system.

How does the ABC Machinery Cooling System work?

Theoretically neither the extremely high temperature nor the pressure produced during pelletization could be changed in the compressing chamber, under the severe working conditions of which the ring die may get cracked and lose effectiveness in a short working time (normally less than 200 hours) with the co-effect of alternating stress produced by tensile and compression and thermal stress. At the same time the grease for the roll bearing of the ring die melts down and runs away under the high temperature and pressure, which causes damages to the bearing in high frequency (in 2 hours to 2 days).

However, the compression molding is completed in a short time through the inner ring and the compression holes. Therefore, if the temperature at the non-molding area could be lowered, which would guarantee the proper compression of the pellets, the ring die and bearing would be cooled down, and their working life would be extended. The technical assumption is proposed and applied into production firstly by ABC Machinery in China and internationally. According the equipment layout, ABC Machinery makes use of air cycle to cool down the temperature and remove the extra water vapor, improving the working environment of the non-compression area, lengthening the working life of roll bearing, making production continuous and lowering the production cost effectively and eventually.

Since ABC Machinery has adopted the temperature control technology for the inner system of ring die in 2008, the temperature in the compressing chamber is lowered from over 100 ℃ to around 50 to 90 ℃, at which temperature the alternative stress becomes “mild”. And since 2008, none of the ring dies equipped in ABC Machinery pellet mills or in pellets production systems have cracked, the average productivity of each ring die higher up from 250 – 300 T to 800 to 1000 T, with the highest productivity of 1500 T, and at the meanwhile the production cost lower from 25 – 30 RMB to 5 – 7 RMB.