Why do you need PLC system for biomass pellet plant?

HS-PLC Pellet Mill Automatic Control System is designed and invented by ABC Machinery Research and Development Center to improve the productivity, lower energy consumption, and secure the maintenance of the biomass pellet plant. The system automatically controls the feeding amount and the mixing of the raw materials according to the working conditions of the pellet mills, putting the pellet machines into the best operational performance, which increases the work efficiency and productivity of the pellet mills and saves energy to a large extent. In addition, the multi-functional system can provide various services such as runtime history checks, timely maintenance reminders, etc.

Composition

It is generally composed of Programmable Logic Controller (PLC); frequency converter; temperature, torque and moisture transducer; control system and low-voltage apparatus, etc.

Working principles

HS-PLC Pellet mill automatic control system is composed of the Observation system for the principle computer, SIEMENS PLC S7-300 and S7-200, Profibus DP and Frequency converter, etc. With the host system and operating on touch screen, the parameters are set (such as the parameters on productivity, moisture content, etc); the data information is displayed (such as temperature, torque, current, moisture content, etc); the working status can be set and observed, and information provided by the helping center can be gained. Programmable Logic Controller can control the system and have the functions of fault diagnosis, alarming and handling for ABC Machinery biomass pellet plant.

Functions

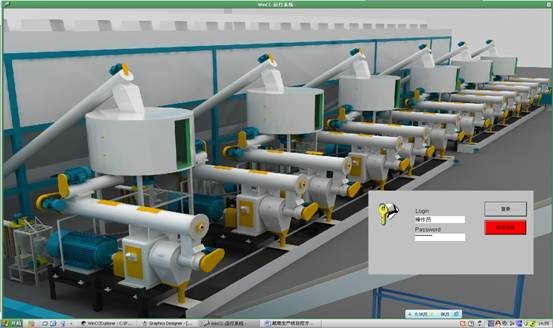

1)It can be logged in by operators with different identities.

When logging in the system, the operator has to choose an identity on the landing interface, shown as the picture (an example project in China, it can be written in multiple languages for your choice):

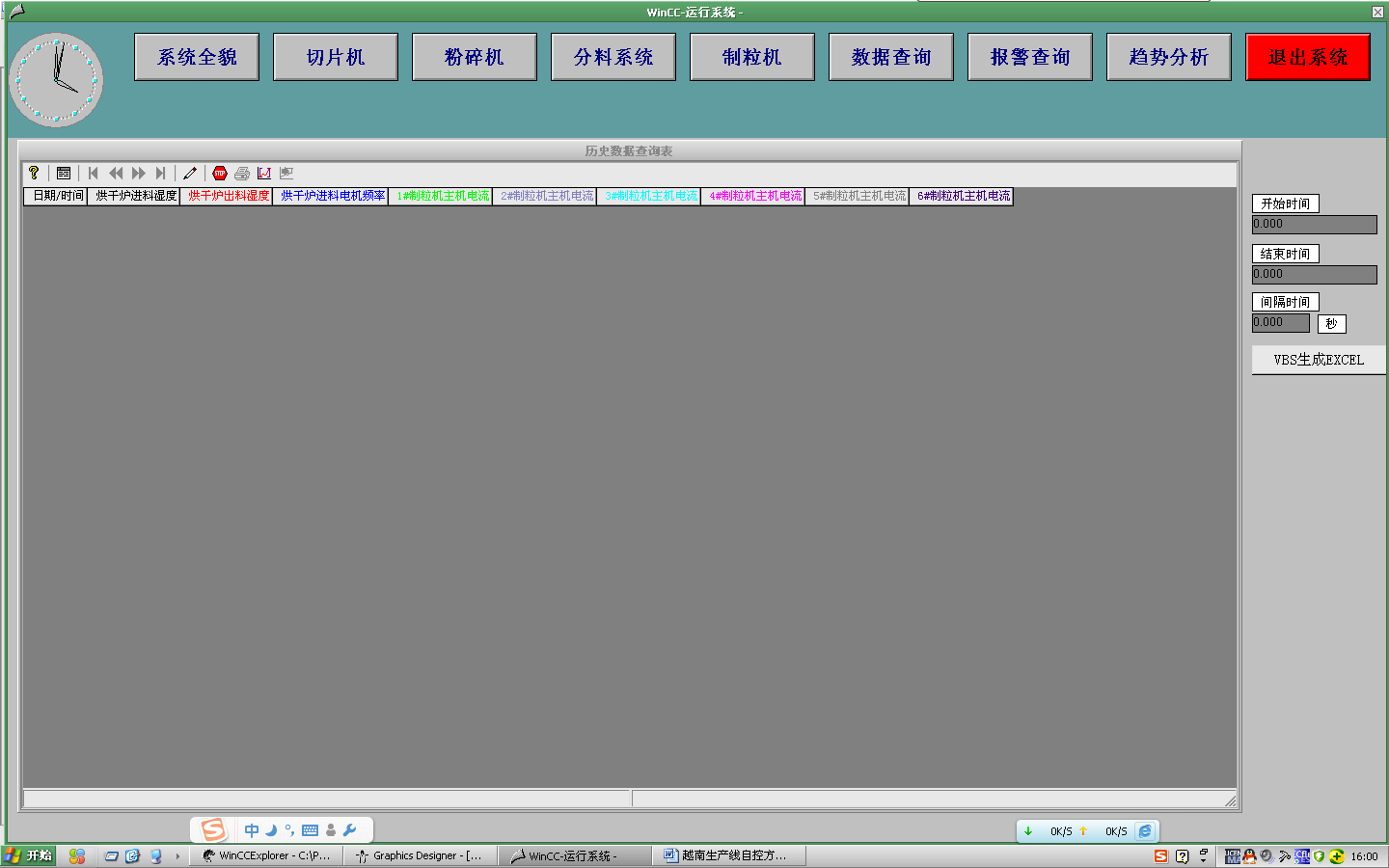

2)Real time monitoring

The first interface after logging in is the main interface where the real time monitoring over entire system can be conducted by clicking on the different functional buttons on the interface, as can be seen below:

Overview of the whole system

3)Switching between manual / automatic operation button

After ensuring the automatic production line runs normally, the operator can click the remote auto button to switch into the automatic operation. In the main interface, the operator can supervise all the processes of each functional sections and the entire dynamic production process of the production line from the feeding of raw materials to the pelletization of the pellets.

4)Remote hand control, flexible operation

When the starting or the stopping of a specific section of or the entire production line is needed under certain circumstance, the operator can press the “remote hand control” button on the main interface, and then choose the corresponding functional button according to the requirements.

5)Alarm Check

Click on the “alarm check” button on the main interface, the system will switch into the alarm recording interface, where all the alarm information is recorded and analyzed by the host system, providing data support for the on-site technicians.

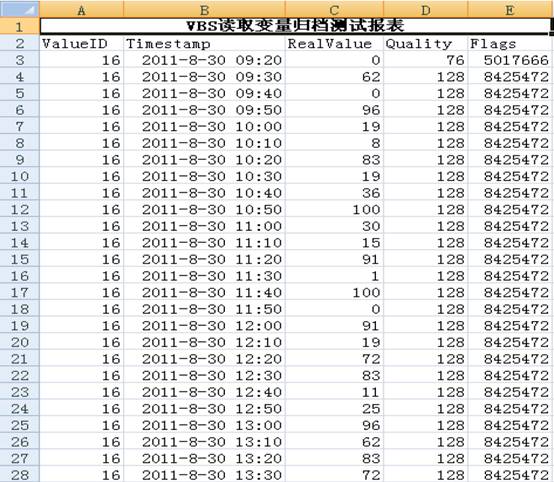

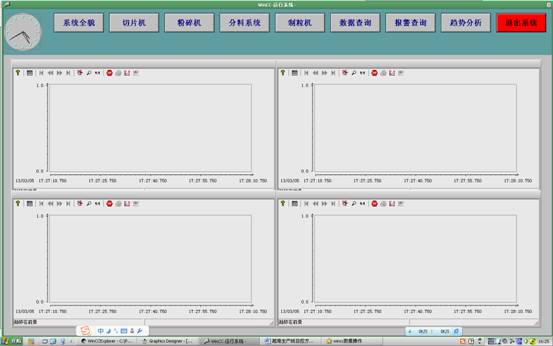

6)Visualized trend analysis

The trend analysis interface will be presented after clicking on the “trend analysis” button. On the trend analysis interface, the system operational parameters will be presented in visualized diagrams and the trend of the system operational parameters can be observed clearly.

The HS-PLC Pellet Mill automatic control system adopts the advanced technology in the field, with independent intellectual property rights, accredited by Nanjing Municipal Transformation Projects of New and High-tech Achievements, winning a good reputation among clients.