The No.1 choice for small scale pellet production!

Quickly put into production! High investment return!

If your budget is limited and you don’t have much raw material, this is the ideal biomass pellet project for you.

Project Description:

Power: 127.5KW (with drier); 109.5KW (without drier); 200KW (with crusher and drier)

Capacity: 1-1.5 t/h biomass pellets (depending on the type of raw material)

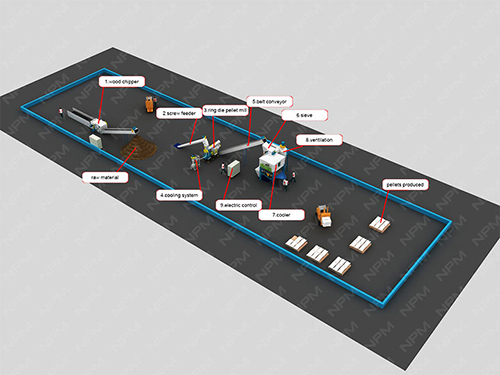

The 3D model layout for biomass pellet plant with capacity of 1-1.5 t/h

Your biomass pellets will be produced following this process flow:

Crusher/chipper equipments → conveyor → sieve → small drier (not necessary if the raw material has a fine moisture) → screw feeder → ring die pellet mill (model 420, 1 set) → conveyor → cooling system → bagger

In this project, we will also provide you with the following equipment based on your requirements:

Electric control system, cooling system for ring die pellet mill, cooling system ventilation, dedustor, iron removal system

This main features of the pellet line are the follwing:

- Simple structure, only one main machine (ring die pellet mill) required

- Small space required (800-1500㎡), making it easy to control the ash produced

- Labor saving, few people required

- Easy maintenance