If your location allows you to collect and store large quantities of material, we definitely suggest you to choose this plant even if you need a higher investment, as we can guarantee you a profitable economic return.

- The output can reach 20 t/h, which means 150,000 t/y. No matter what output quantity is required, we can help you according to your requirements.

- This large biomass pellet line is the preferred choice for our international customers. Check out the project list to see some examples of pellet plants that we have previously installed.

- The modular, replicated parallel design, PLC control and steam-line production allow high efficiency and prevent equipment failure.

Project description:

Both the power and the capacity (above 3 t/h) are designed as per your requirements.

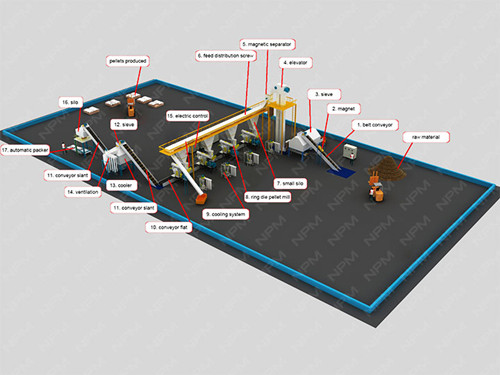

The 3D model layout for biomass pellet plant with capacity of +3 t/h

Your biomass pellets will be produced with this process flow:

Conveyors (x sets) → sieves (x sets) → large drier (x sets, not necessary if the raw material has a fine moisture) →temporary feed storage → lifter → feed distribution system → screw feeder (x sets) → ring die pellet mill (model 420 or 508, x sets) → long conveyor → larger cooler → silo → automatic weighting system.

In this project, we will also provide you with the following facilities based on your requirements:

Electric control system, cooling system for ring die pellet mill, cooling system ventilation, dedustor, iron removal system.