Raw materials with a suitable size before being pressed also require a proper moisture level. For instance, before making wood pellets, you need to control the moisture of sawdust between 12% and 18%. If the moisture level is too high, the pellets produced are easy to break, whereas if the moisture level is too low, it is difficult to form a pellet. In ABC Machinery, we use a drum dryer to process the moisture.

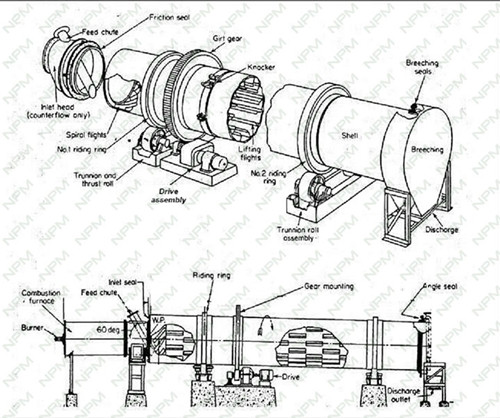

Working principle of the rotary drum dryer

A rotary dryer consists of shell, lifting flight, drive assembly, support system and seal, etc. The wet material is fed into the hopper by belt conveyor or bucket elevator and then transported into the inlet head by feeder through feeding chute. The drum dryer is a slight sloped cylinder to the ground. The material is fed into the higher end, meanwhile the cylinder is heated from the lower end. In this way, the material and the hot air meet in a counter flow.

As the cylinder is rotating, the material is moving towards the lower end. During the movement, the moisture in the wet material is delivered to the hot air. Moreover, the lifting flights mounted in the inner wall carries the wet material to a higher point, the wet material is then dropping and spreading by gravity, increasing the contact area with hot air, accelerating the drying process.

The dried material eventually is discharged and the hot air needs exhaust after separated by a cyclone.

The rotary drum dryer feature in large capacity, low fuel consumption, low drying cost.

| Model | HS-D800 | HS-D1500 | HS-S2800 |

| Drum diameter(mm) | 800 | 1500 | 2800 |

| Moisture before drying | 45% | 45% | 45% |

| Moisture after drying | 15% | 15% | 15% |

| Drying capacity(t/h) | 1-1.5 | 2-3 | 3-5 |

| Total power(KW) | 35 | 45 | 67 |